MOREX

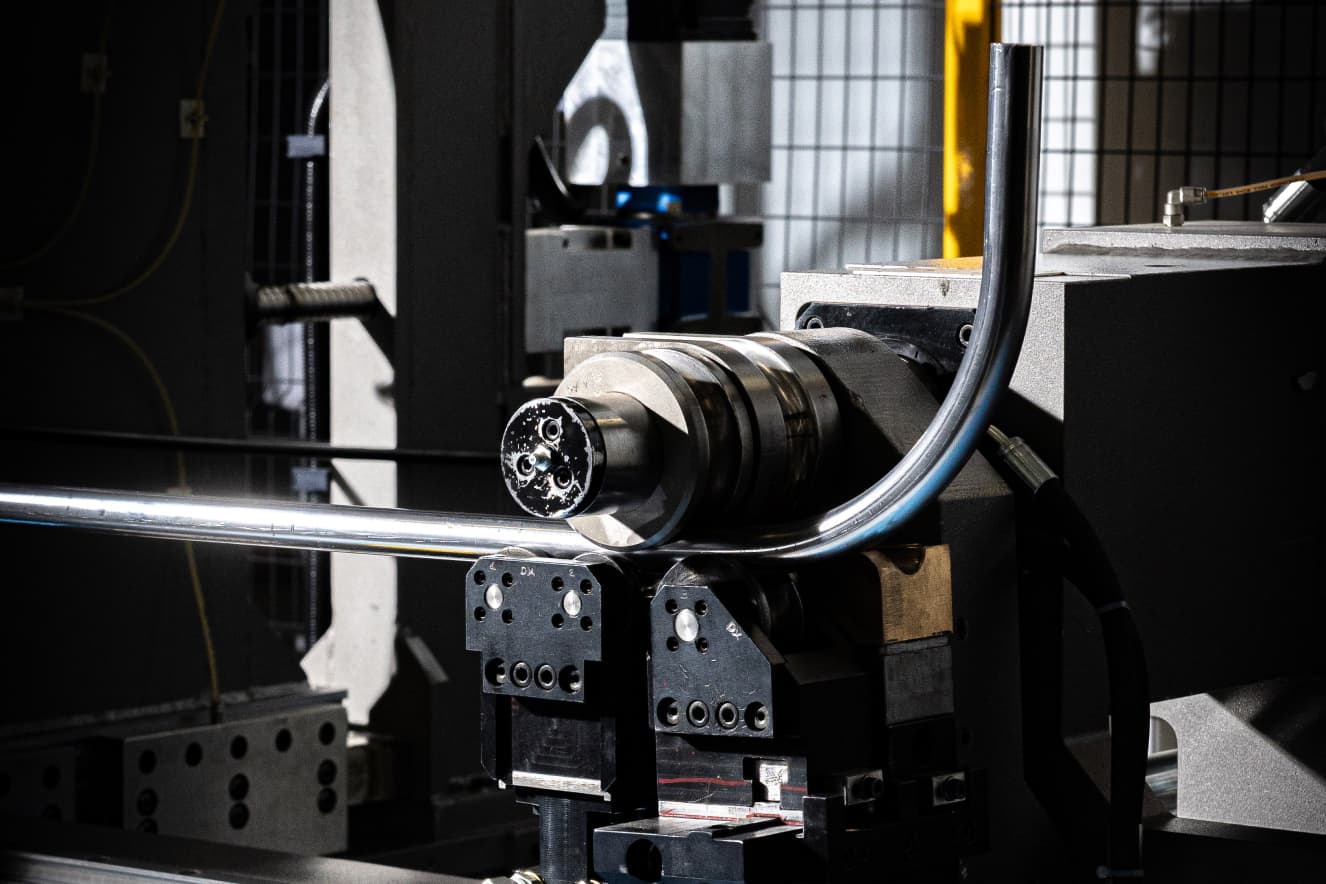

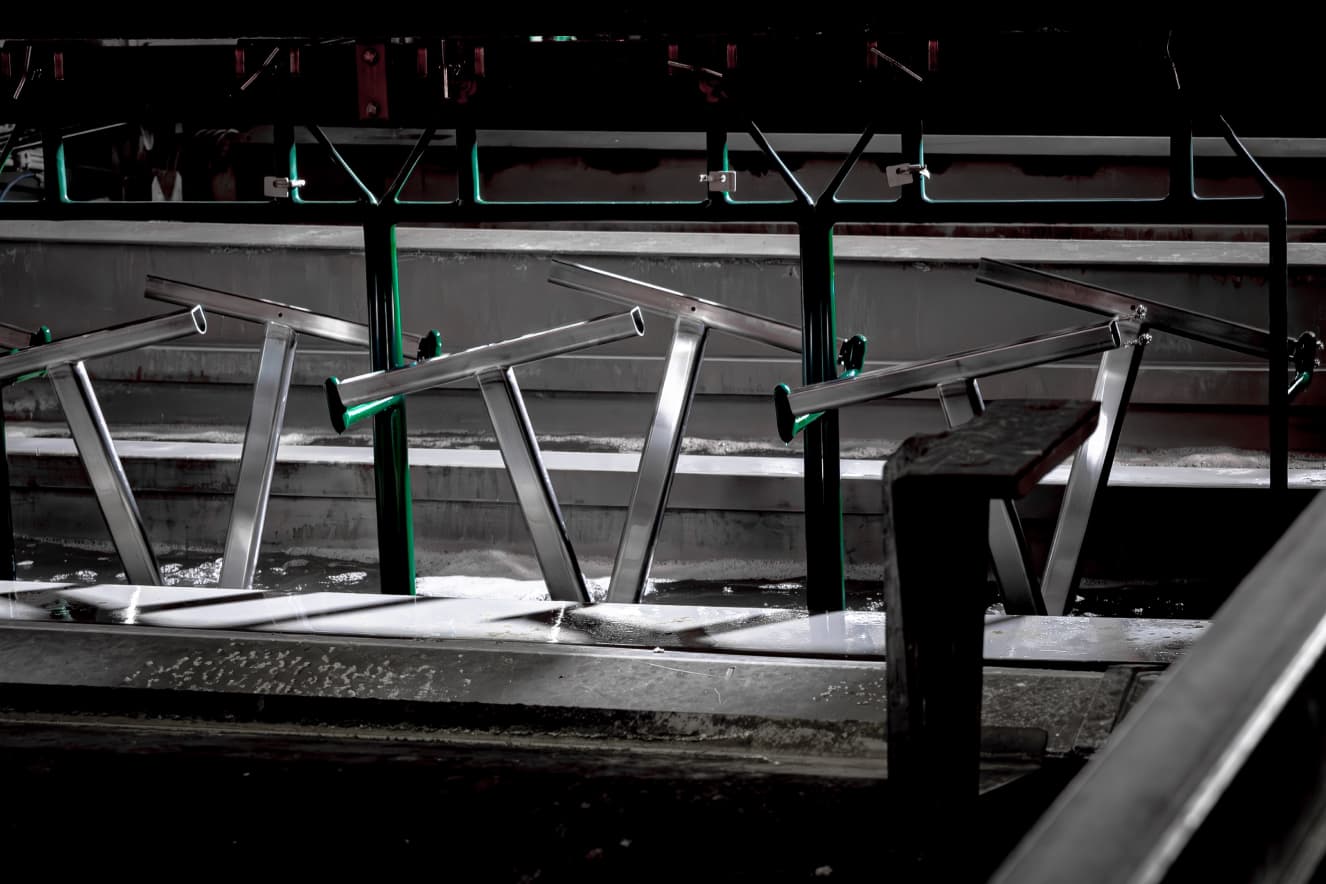

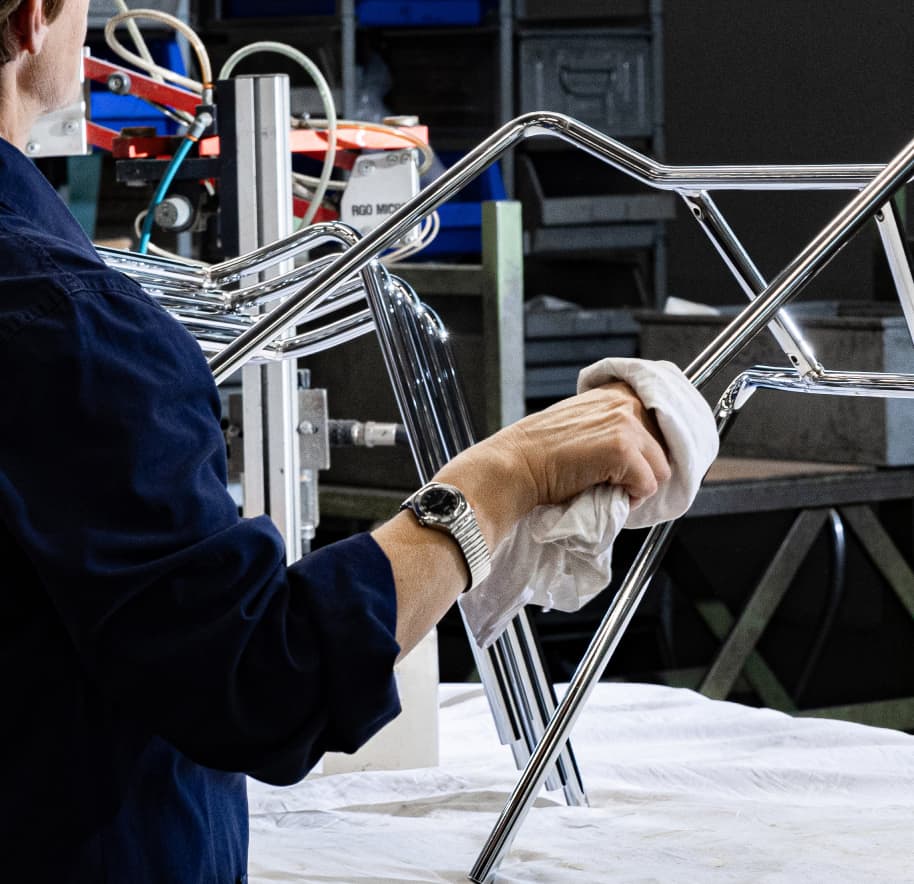

Metal furniture production

Founded in 1973, Morex is today a leading European company in the production of high quality metal components. Thanks to its long experience, its products are recognized and appreciated by the most prestigious industries in the furniture sector.