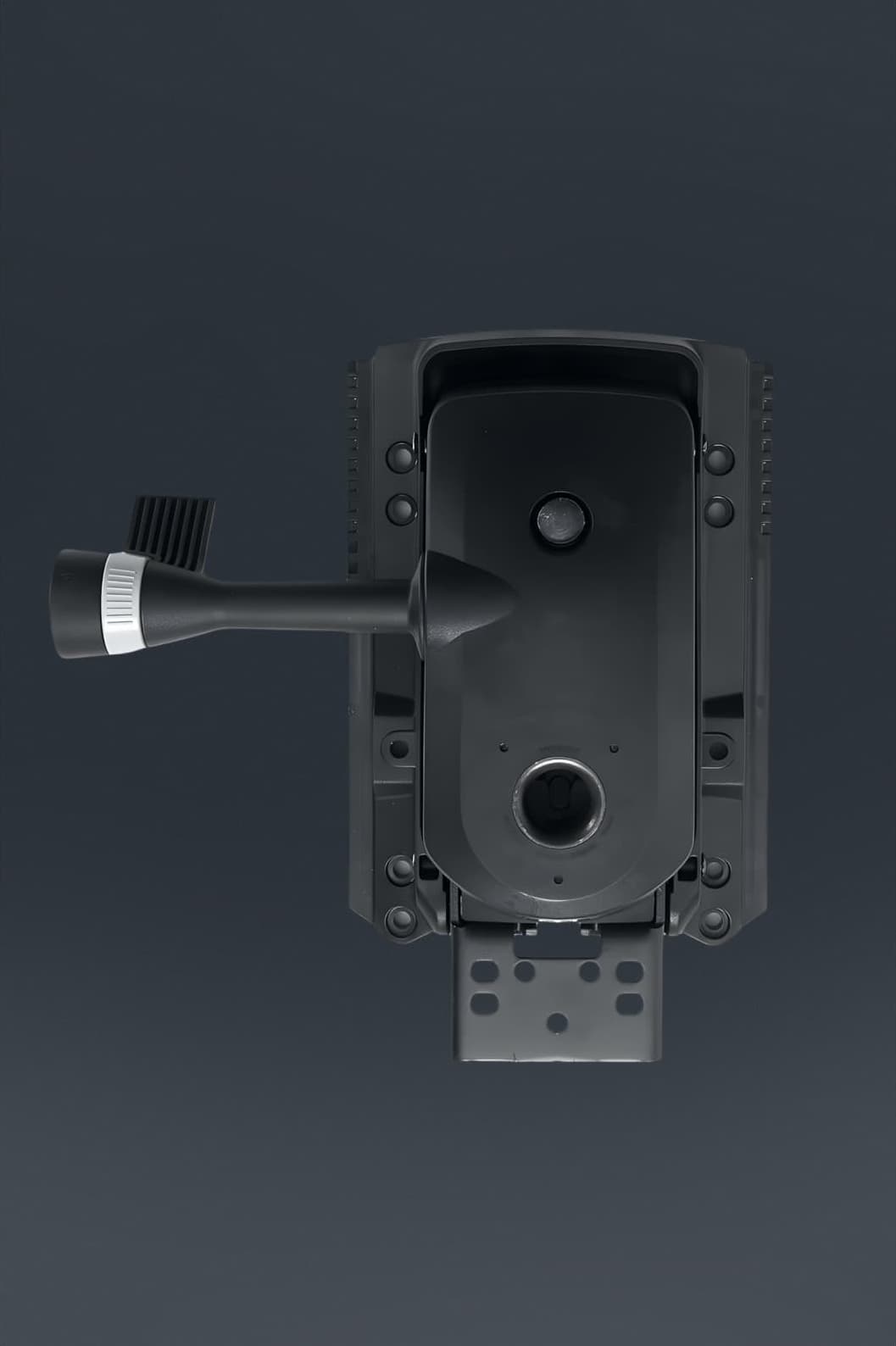

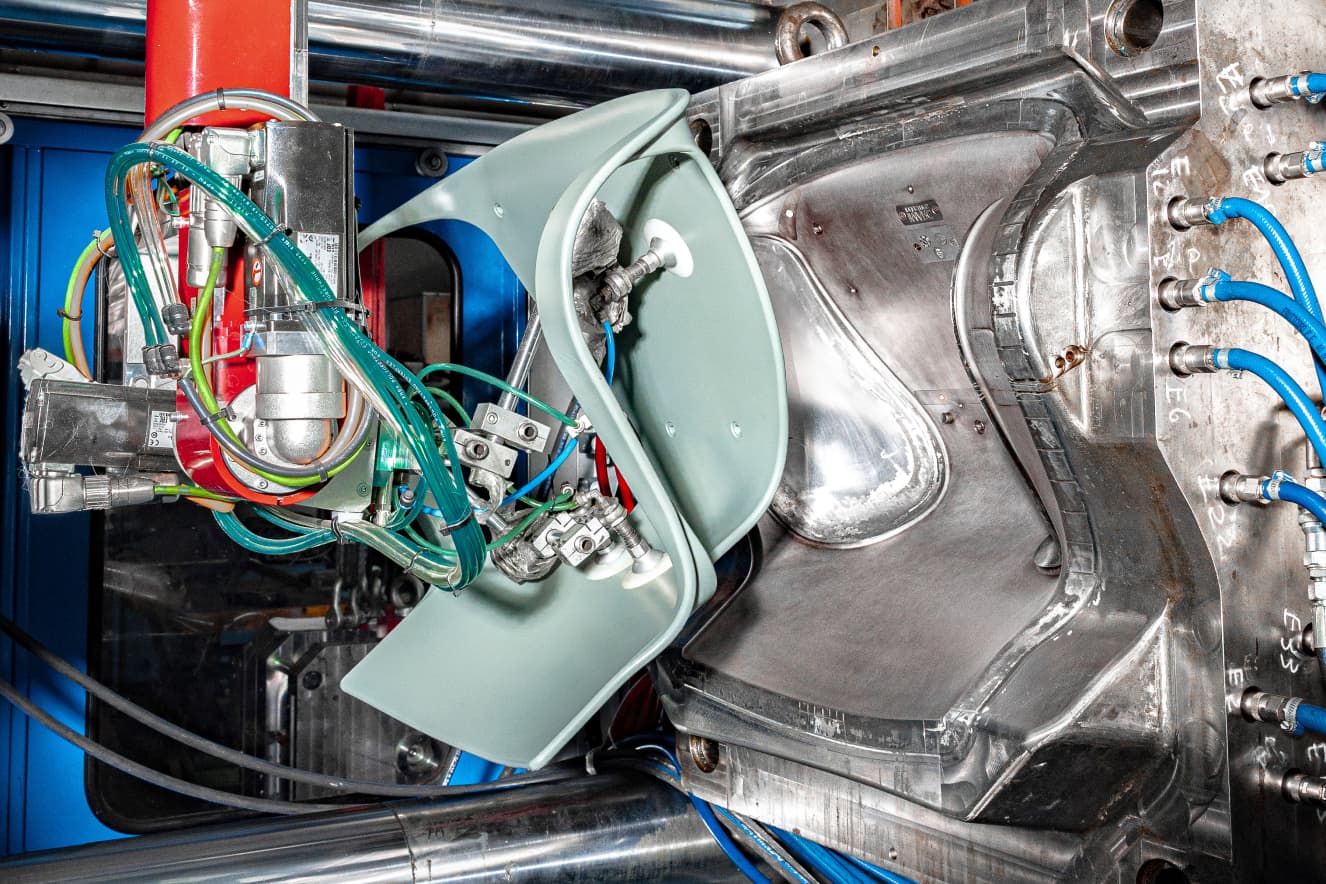

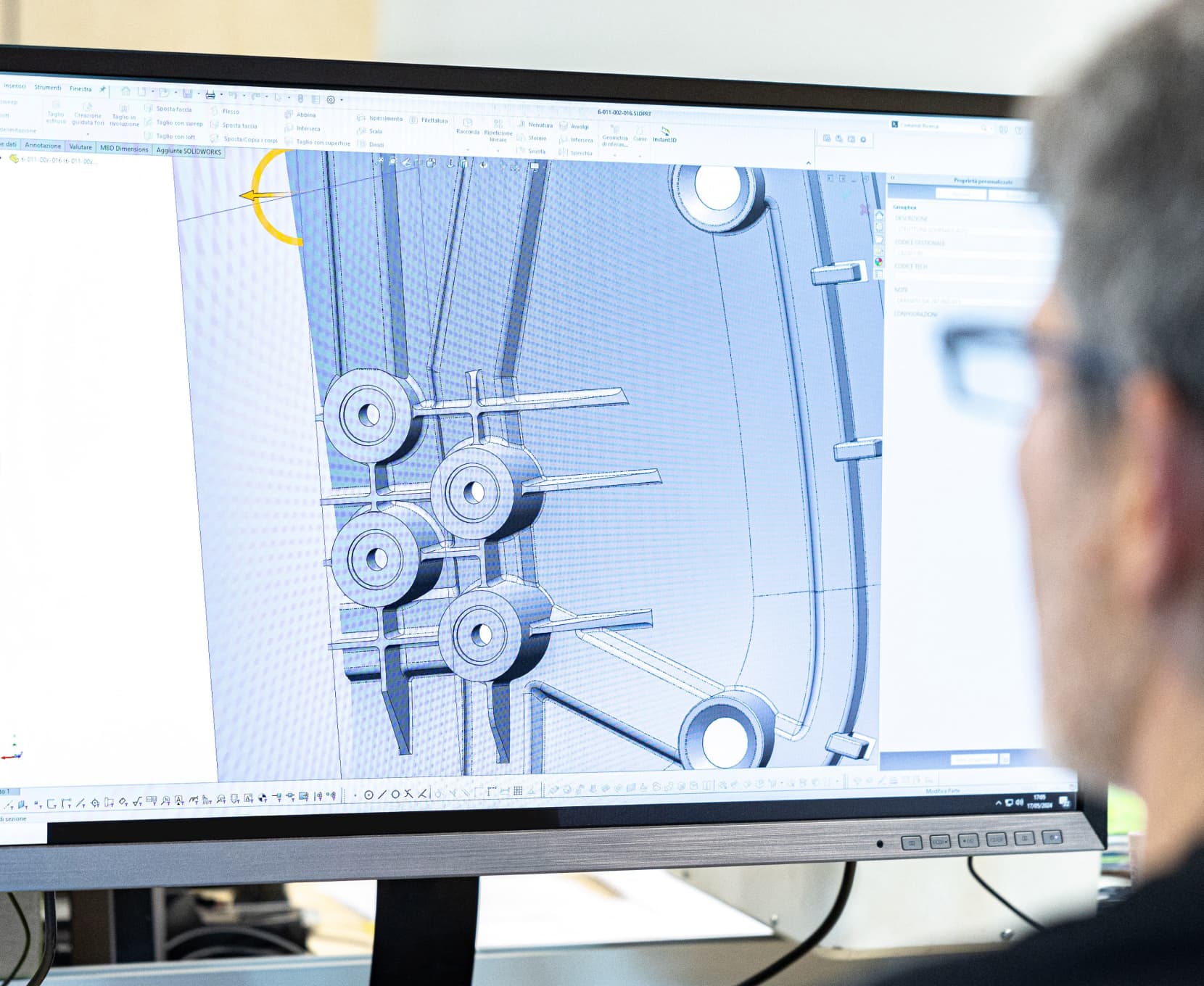

Modular solutions

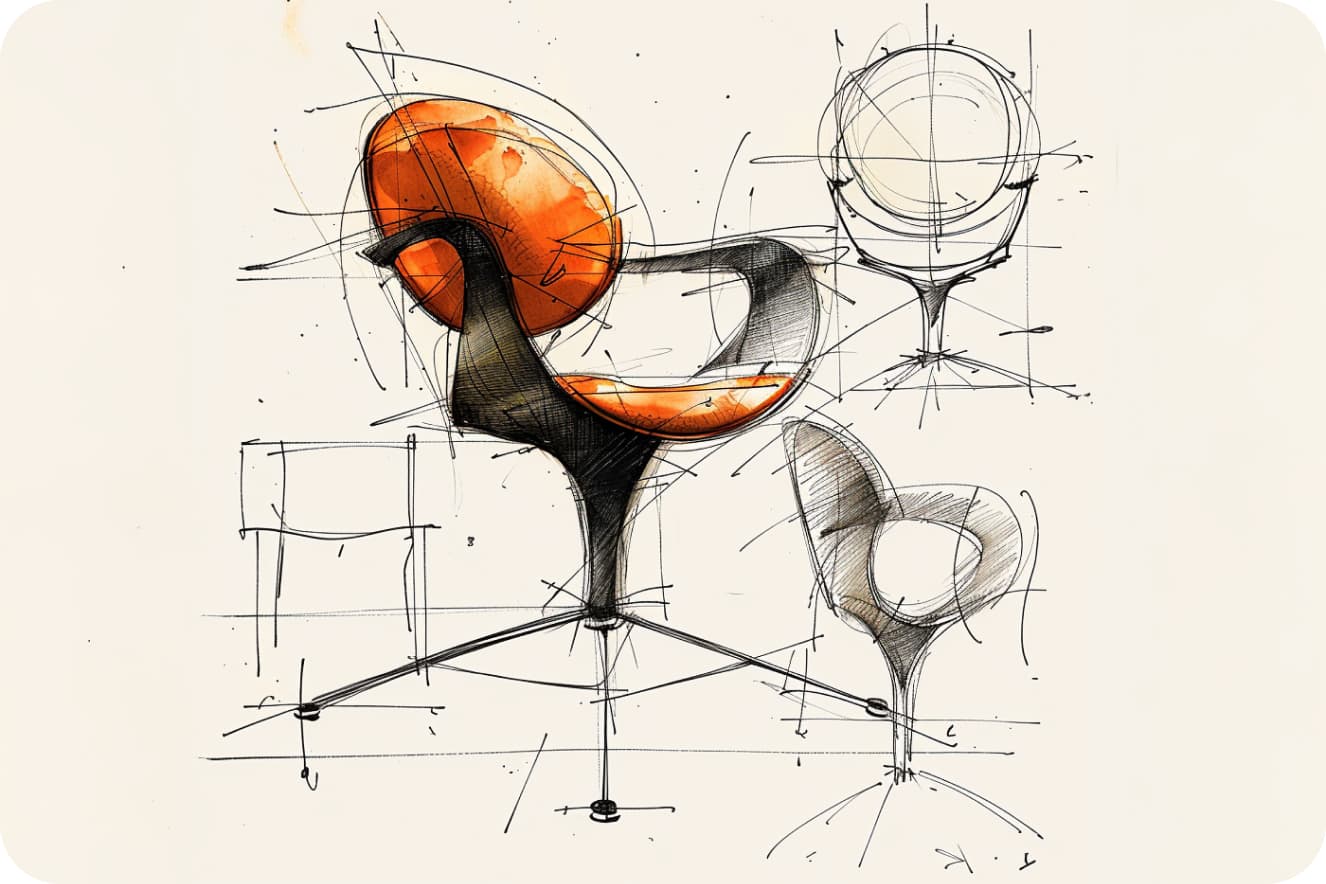

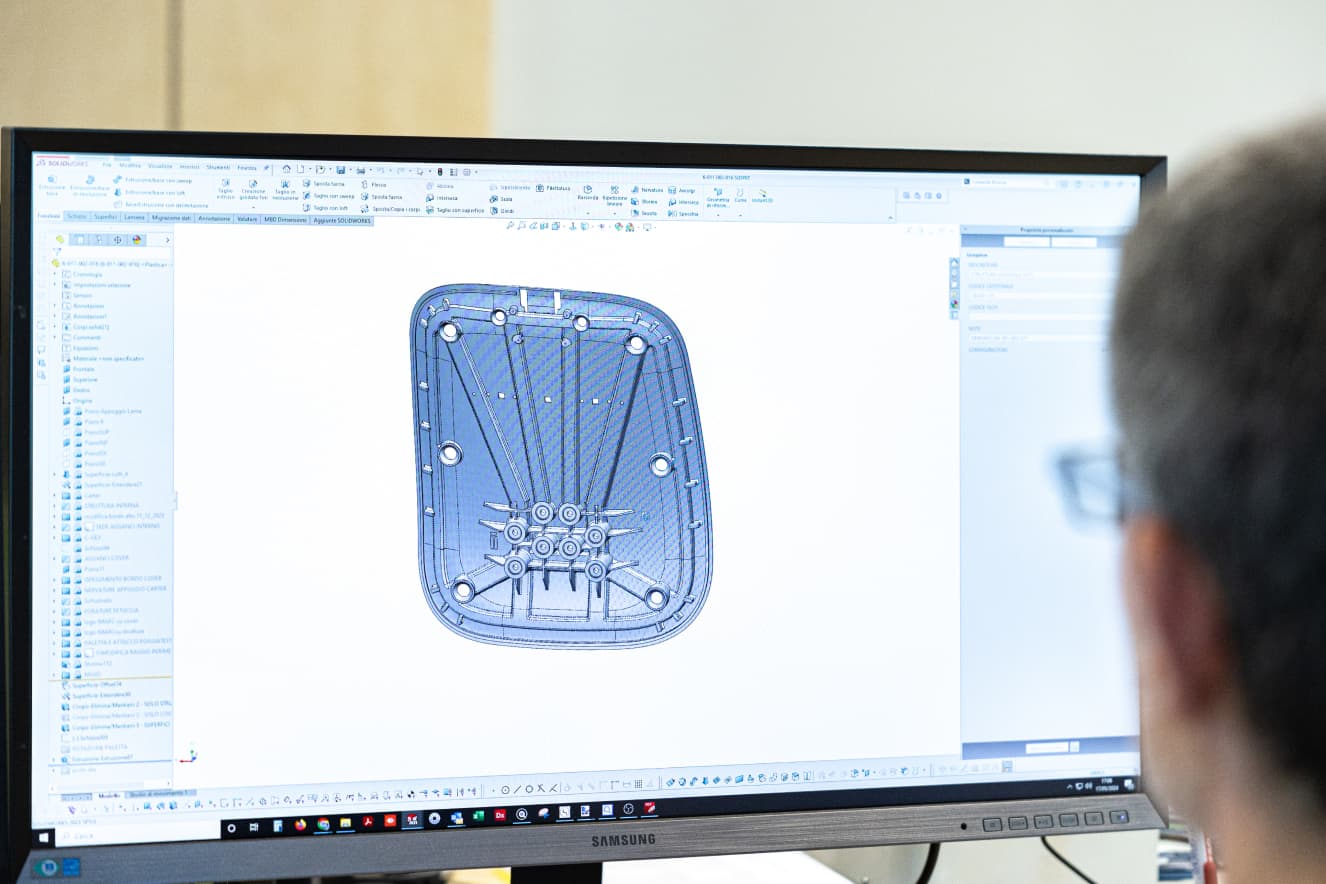

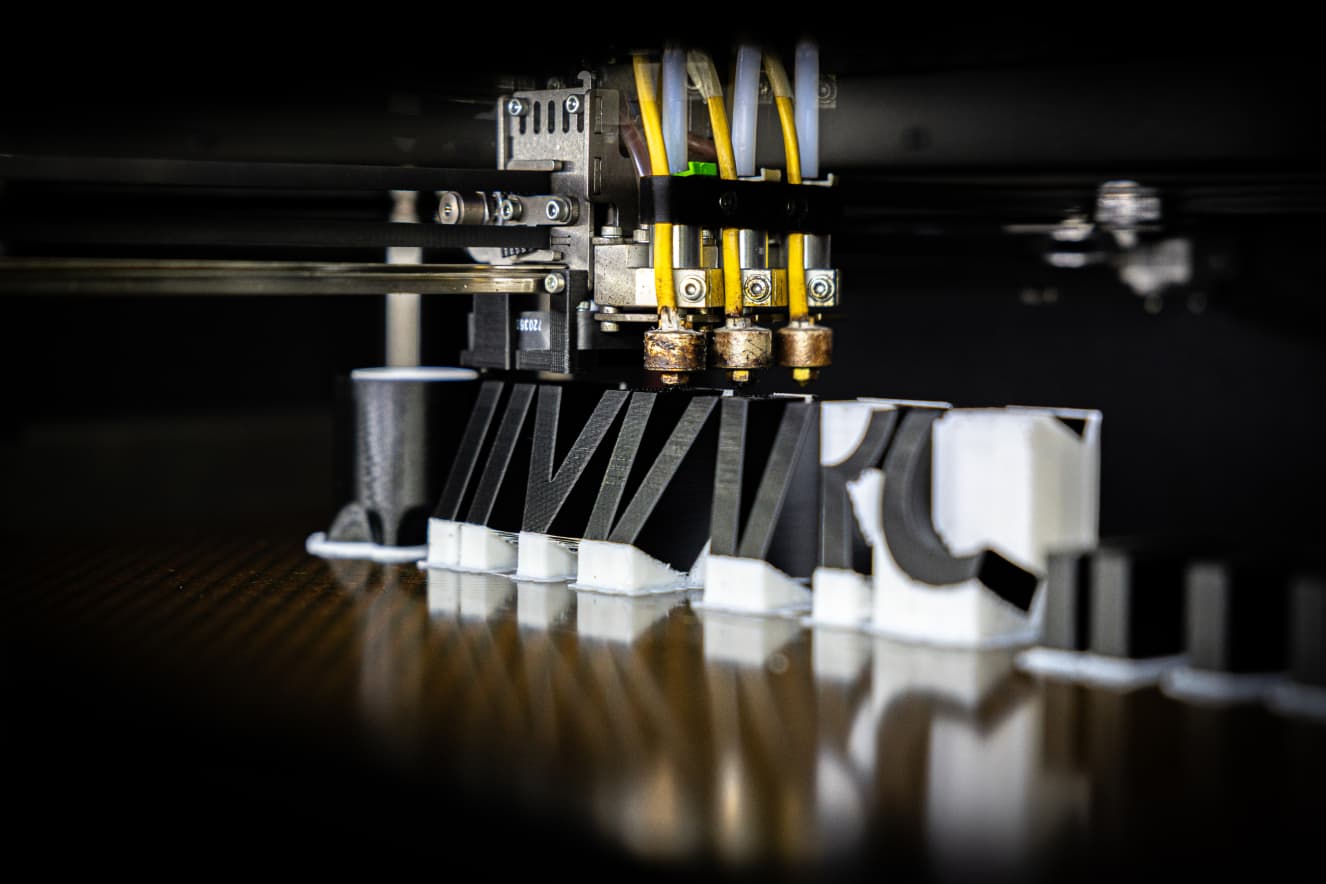

From the design of a single component to the creation of the entire chair in kit, Imarc accompanies its partners in every phase of the process. From the development of the initial idea, through engineering and mass production, to the definition of packaging and delivery methods. Each step is guided by a shared goal: to transform the original project into a real product!